Description

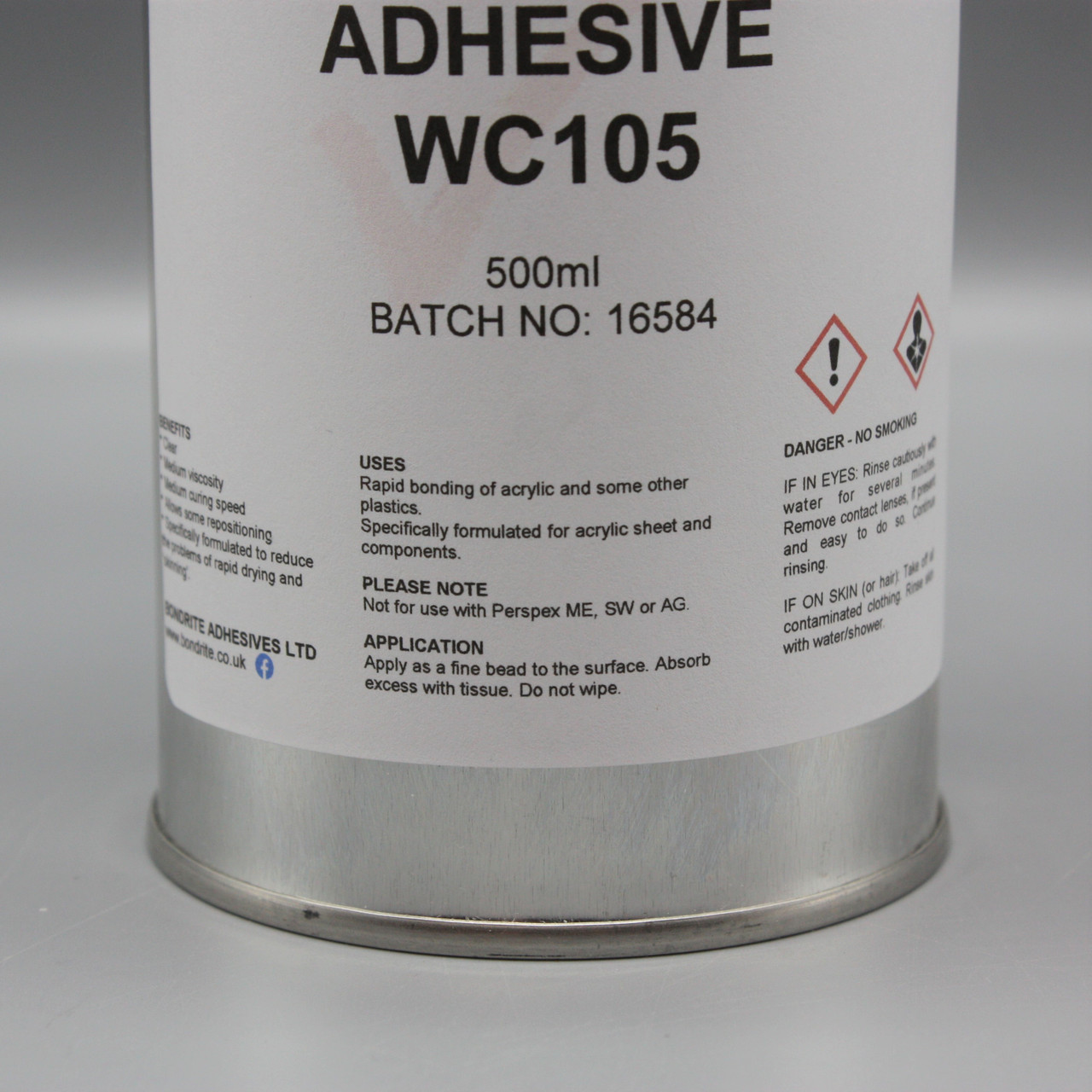

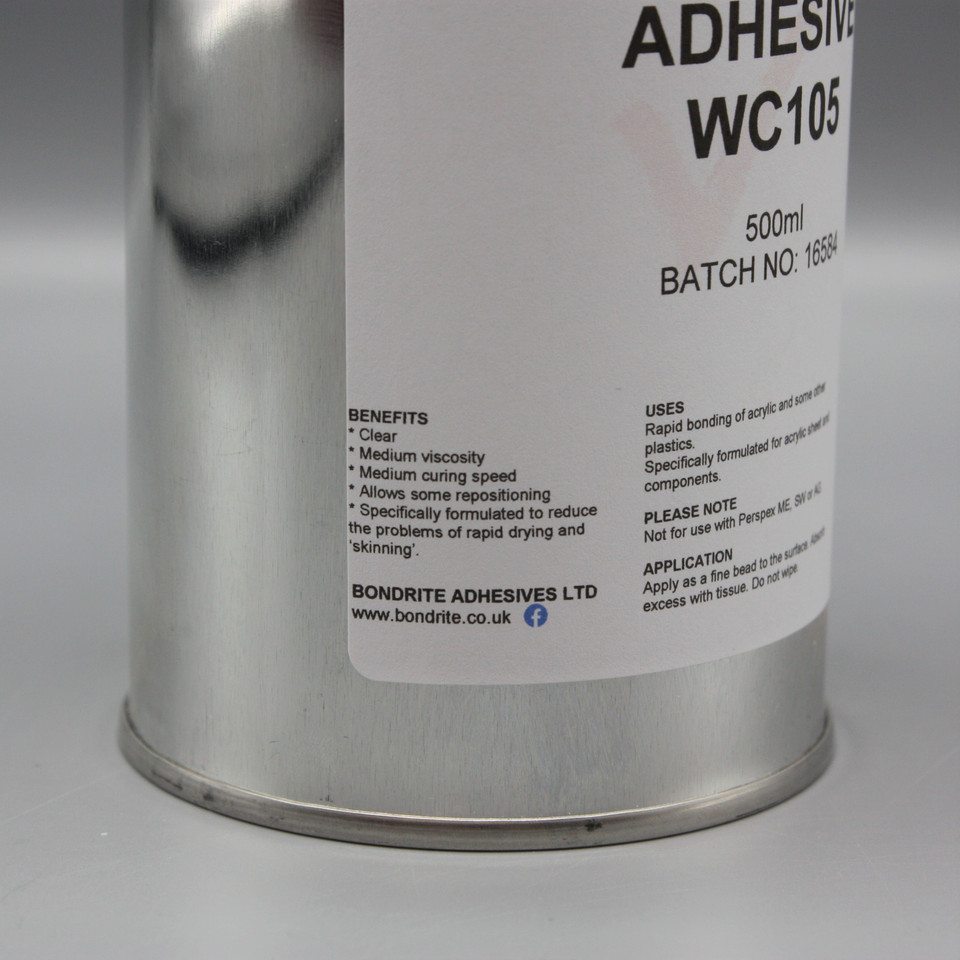

This Acrylic Adhesive WC105 is clear, has a medium viscosity and specifically formulated for acrylic sheet and components.

WC105 acrylic adhesive can be used across a wide range of industries and applications where the rapid bonding of acrylic and some other plastics is required.

Application uses

This acrylic adhesive is ideal for, or known as:

- Rapid bonding of acrylic & some other plastics

- General fabrication work

- Joining items made from ‘Diakon’ acrylic polymers as well as cast acrylic (Perspex)

- Acrylic Sheet Adhesive

- Acrylic Weld Cement

- Acrylic glue

- Acrylic adhesive

- Gap fill acrylic

- Acrylic plastic glue

- Acrylic plastic adhesive

- Plastic adhesive

- Plastic sheet adhesive

- Plastic weld cement

WC105 acrylic adhesive cannot be used with: Perspex ME, Perspex SW or Perspex AG grades.

Variations of this adhesive

This adhesive comes in a few versions, these being:

- 500ml Acrylic Adhesive – WC105

- 1 Litre Acrylic Adhesive – WC105

WC105 acrylic adhesive is also available in 2.5 Litres, if you require this volume, please call the office on 01509 815550 as this is not available through the website.

Adhesive composition

WC105 is a ready-mixed, colourless, solvent-based adhesive. It consists of acrylic polymer and methyl methacrylate monomer dissolved in solvents.

Hardening

WC105 acrylic adhesive hardens as the solvent is absorbed or evaporates, depositing polymer in the joint. In addition, the solvent softens the surface being joined so that they fuse, hardening as the solvent migrates into the body of the substrate.

Reduce rapid drying problems

The adhesive has been specially developed to reduce the problems of rapid drying and ‘skinning’.

Adhesive benefits

This adhesive has the following benefits:

- Medium Viscosity;

- Medium Curing Speed;

- Allows some repositioning.

Adhesive information

| Polymer Base | Methyl Methacrylate |

|---|---|

| Bonds | Acrylic |

| Specific Gravity | 12 approx. |

| Solids | 20% |

| Viscosity | 600mPs approx. |

| Storage | 5°C-25°C |

Directions For Use

Although WC105 was developed so that rapid evaporation and skinning are minimal, the following techniques will reduce these problems further:

- Limit exposure to air before applying the adhesive – Dispense the adhesive directly into the joint using a small flexible polyethylene bottle with a suitable nozzle or hypodermic syringe with a shortened wide-bore needle.

- Use a dispenser which holds no more adhesive than is needed for the job. Prevent the nozzle or needle becoming clogged by inserting a pin or wire into it whenever the dispenser is not being used.

- Reduce the evaporation that occurs between applying WC105 and assembling the parts – In extreme heat conditions it is beneficial to refrigerate the adhesive for at least 12 hours before use. A domestic refrigerator is suitable (temperature 5° – 10°C). If this is not possible, an alternative is to cool the adhesive containers in cold water, although this is less effective.

- NB: Always re-cap the tin immediately after use.

- The initial cure takes about three hours at room temperature but the joint should not be machined for at least twenty-four hours. Full cure takes place within 48 hours but bonds reach their maximum strength after about three weeks at room temperature. For most applications, one or two weeks should be adequate.

Precautionary information

- The gap-filling properties of the adhesive are limited which means that mating surfaces must be machined to close tolerances.

- Do not use WC105 for sheet laminating as the absorption of the solvent is likely to cause distortions and/or crazing.

- The solvent in WC105 may cause soluble colourants to migrate from one piece of cast acrylic (or other plastic being used) to the next. If colour is important, check for any migration by making a small test joint.

- Unopened containers do not need to be stored in a refrigerator.

- Always replace the lid of the container immediately after use to prevent evaporation of the solvent.

- THIS ADHESIVE IS NOT RECOMMENDED FOR STRUCTURAL APPLICATIONS ON AIRCRAFT.

Customer asked questions

Question: Do you have a product that will stick Perspex-type materials used in shop windows?

Answer: As with all jobs, it depends on what you are sticking it to. If you are sticking PMMA (of which one brand is Perspex) to itself, then we recommend either Acrylic Adhesive – WC102, Acrylic Adhesive – WC105 .

Each has a different application method as described on our website, and we are happy to talk through this with you if you are unsure. If you are bonding to different substrates then we need to know what they are to suggest the best product.

Acrylic Adhesive price

If you buy this Acrylic Adhesive in bulk, we offer a discounted rate making it even better value for money.

Not sure if this Acrylic Adhesive is right for your requirements?

If you are not sure if this adhesive is correct for your requirements, please contact us to discuss your requirements and we can point you in the right direction.

John unwin –

Worked very well, as described, fast delivery.